What is Industry 4.0?

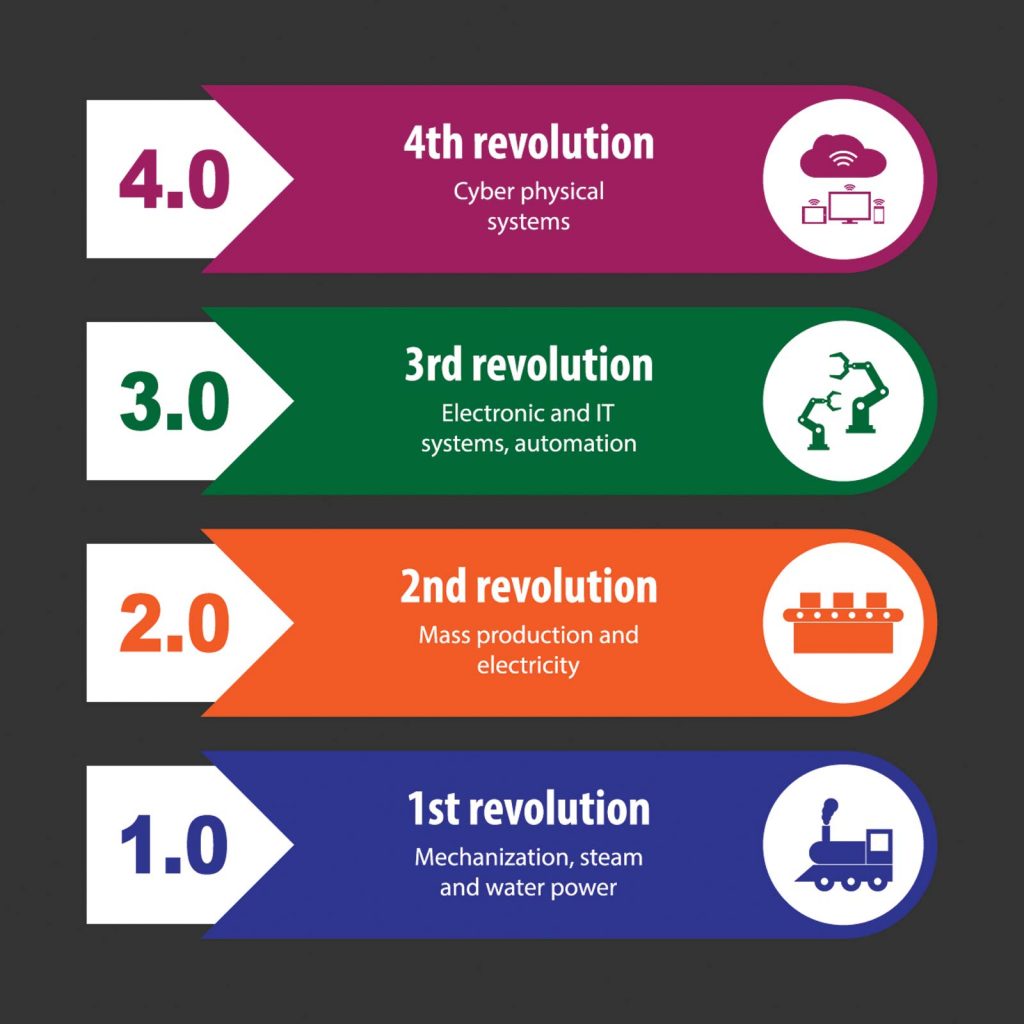

To understand the term being thrown around more and more frequently in industry, we must first explore the three industrial revolutions that have culminated in the world of manufacturing we know today.

Industry 1.0: “The Industrial Revolution”

In the 1698 century, the first steam engine was built by Thomas Savery. A few iterations and some major improvements later, in the late 18th century, the steam engine was becoming a common tool for powering mechanical production. Industries such as textiles, which were previously reliant on manual labour for output, were completely revolutionised by the speed, quality and efficiency with which products were made, compared to previously slow, labour-intensive practices.

Industry 2.0: “The Second Industrial Revolution”

In the beginning of 20th century, the invention of electricity sparked a new revolution of industry. Electrical machines were more economical to operate and maintain in terms of both cost and effort. In comparison, water and steam powered machines were resource hungry. As pre-existing industries grew, newer industries – such as steel and oil – expanded, and focus shifted from “getting the job done” to “getting the job done in the most efficient way possible”. This resulted in the beginning of manufacturing principles that are still relevant today, like JIT and lean manufacturing, workplace optimisation and resource allocation techniques.

Industry 3.0: “The Digital Revolution”

In the late decades of 20th century, technology advanced from analogue electrical and mechanical devices to the digital technology we are familiar with today. Integrated circuits bore automated machines, allowing for increased speed and greater accuracy, with reduced human-effort. This advancement resulted in the formation of the field of Supply Chain Management, due to dispersal of geographical locations of manufacturing.

We’re almost up to speed, and I am sure you can identify how each of the 3 industrial revolutions discussed have contributed to moulding the automotive/ manufacturing industry we know today. However, it doesn’t stop here, as we are amid a 4th revolution- “Industry 4.0”.

Industry 4.0

Where the 1st, 2nd & even 3rd industrial revolutions said, “humans, make way for this machine that will perform your job better & faster”, Industry 4.0 is here to say, “how can we improve this technology to make it easier for you, the technician, to do your job better?”

Industry 4.0 builds on the first digital revolution, embedding technology further into our societies, production lines, homes and even human bodies. While many fear that this most recent revolution may pose a threat to jobs as “the robots take over”, this is a misconception. The major difference between this revolution and its 3 predecessors is that this revolution is characterised by integrating human society with technology, rather than replacing humans with technology – particularly in the South African market, where the workforce pool is large and far more affordable than the creation of artificial intelligence to replace these resources. Where the 1st, 2nd and even 3rd industrial revolutions said “humans, make way for this machine that will perform your job better and faster”, Industry 4.0 is here to say, “how can we improve this technology to make it easier for you, the technician, to do your job better?”.

Industry 4.0 aims to use technology to better our lives – automating mundane, repeatable tasks to free up our time to focus on more important things such as process improvement. Inventions like cloud-storage and -computing allow us to access data from anywhere in the world, and ensure it is stored securely, making it immune to corruption, theft and loss. We are also able to process larger quantities of data, more effectively than ever; with tools such as Microsoft Power BI, you can see, at a glance, a clear, accurate digital representation of the performance of a plant that spans thousands of square metres, containing hundreds of millions of Rands worth of machinery and operated by hundreds of people.

At Checkmate, we are doing our bit to integrate the positive facets of Industry 4.0 into our clients’ work environments by creating capturing- and reporting-interfaces that are intuitive for users, using technology that is secure and can be accessed from anywhere in the world. Checkmate’s price-points and customised approach to creating plant management software allows South African manufacturers of all sizes to get with the times and to start introducing Industry 4.0 principles into their workplaces.

Recent Comments